01 repairable by design

bachelorthesis

group

2021/22

together with my bachelor partner david schöllhorn, we showed what repairable product design can look like. our goal was to inspire and motivate people to repair their products. the result are ten guidelines for repairable design along with three exemplary products on which the repairability is shown.

︎︎︎ facts

through repair, products are given back their actual use and their product life is extended. as a result, fewer new products need to be produced and the energy and resources required for this are saved.

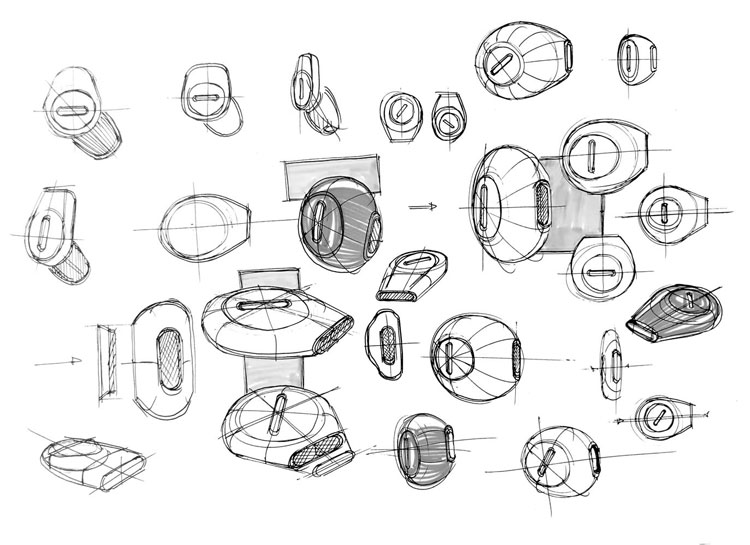

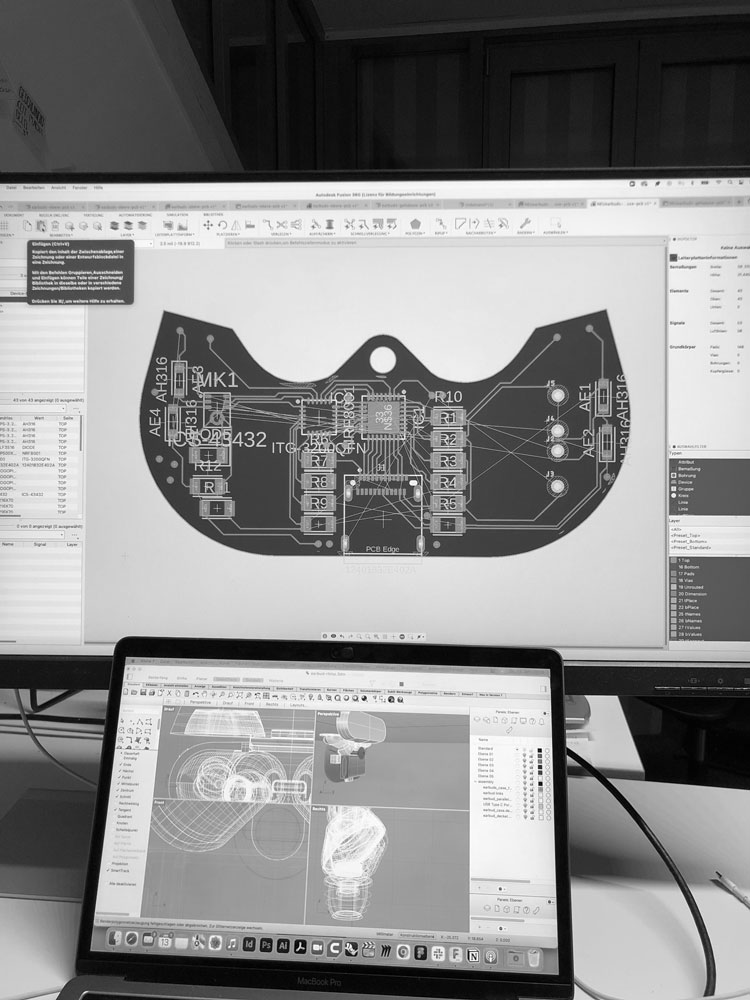

︎︎︎ process

we spoke with many experts from various industries. we visited ifixit in stuttgart and participated in a repair-cafe for a weekend. by disassembling existing products, we understand which problems exist and how products are built.

through repair, products are given back their actual use and their product life is extended. as a result, fewer new products need to be produced and the energy and resources required for this are saved.

︎︎︎ process

we spoke with many experts from various industries. we visited ifixit in stuttgart and participated in a repair-cafe for a weekend. by disassembling existing products, we understand which problems exist and how products are built.

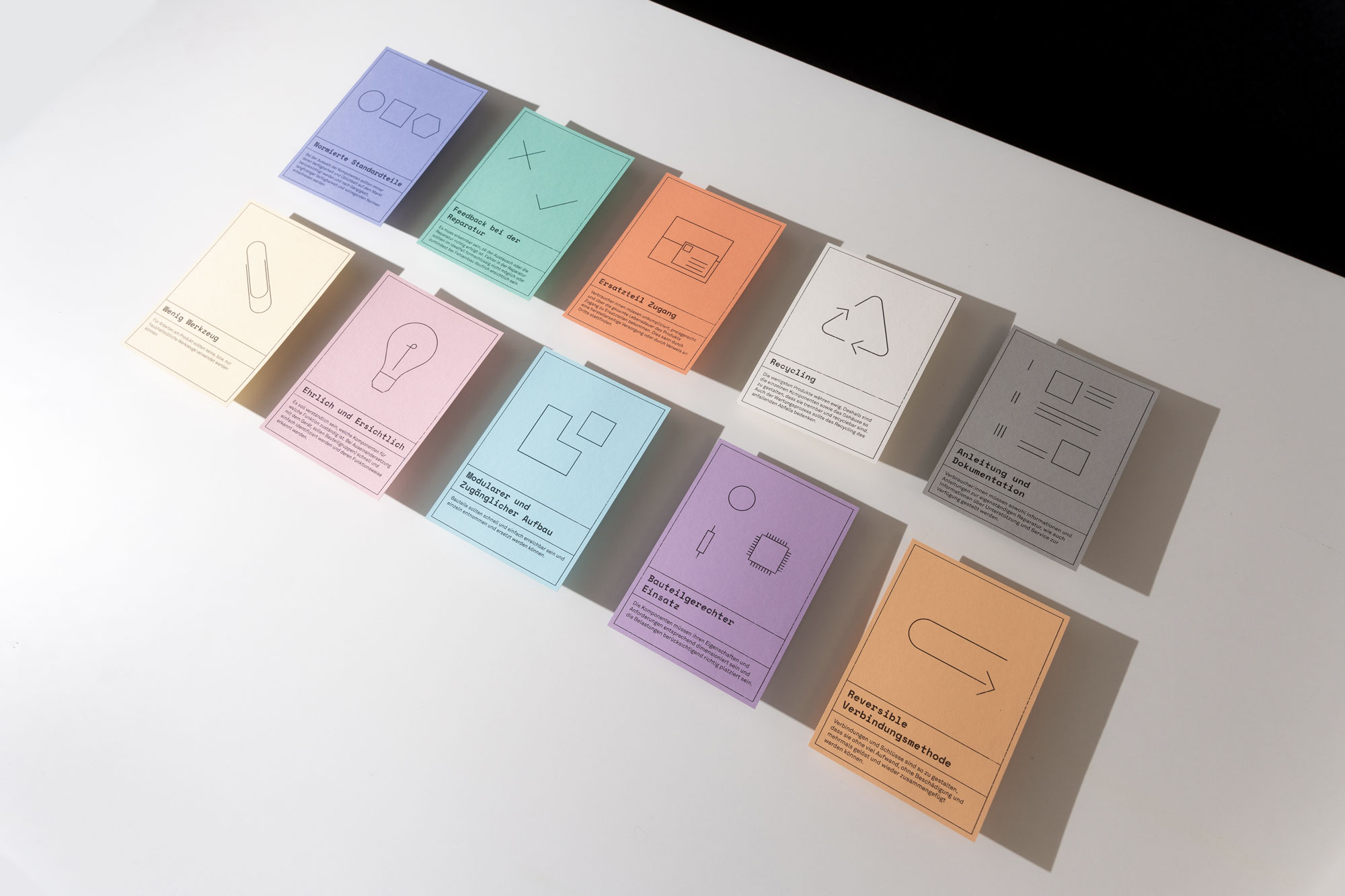

︎︎︎ ten principles for repairable productdesign

the guidelines are intended to create a visual incentive to engage more intensively with repairable product development and to support designers and companies along the way.

the guidelines are intended to create a visual incentive to engage more intensively with repairable product development and to support designers and companies along the way.

reversible connections

connections should be able to be released and rejoined multiple times without damage.

connections should be able to be released and rejoined multiple times without damage.

normed standard parts

when selecting components, their availability and commonality on the market should always be taken into account.

when selecting components, their availability and commonality on the market should always be taken into account.

few tools

no, or only common household tools should have to be used to fix a product.

no, or only common household tools should have to be used to fix a product.

modular and accessible design

components should be quickly and easily accessible and individually removable and replaceable.

components should be quickly and easily accessible and individually removable and replaceable.

recycling

individual components, as well as the housing, are to be designed in such a way that they can be separated and recycled.

individual components, as well as the housing, are to be designed in such a way that they can be separated and recycled.

appropriate use of components

components must be dimensioned according to their properties and requirements, and their placement must be adapted to the forces.

components must be dimensioned according to their properties and requirements, and their placement must be adapted to the forces.

honest and obvious

it should be understandable which components are responsible for which function. it should be possible to recognize components and their functions quickly and easily.

it should be understandable which components are responsible for which function. it should be possible to recognize components and their functions quickly and easily.

spare-parts access

consumers must have access to spare-parts in an uncomplicated manner, at a reasonable price, and throughout the life of the product.

consumers must have access to spare-parts in an uncomplicated manner, at a reasonable price, and throughout the life of the product.

instruction and documentation

information and instructions for independent repair, as well as information on support and service,

must be available to all.

information and instructions for independent repair, as well as information on support and service,

must be available to all.

feedback during repair

it must be possible to see whether the replacement or repair has been done correctly. errors in the repair should ideally not be possible at all or at least be clearly recognizable.

it must be possible to see whether the replacement or repair has been done correctly. errors in the repair should ideally not be possible at all or at least be clearly recognizable.

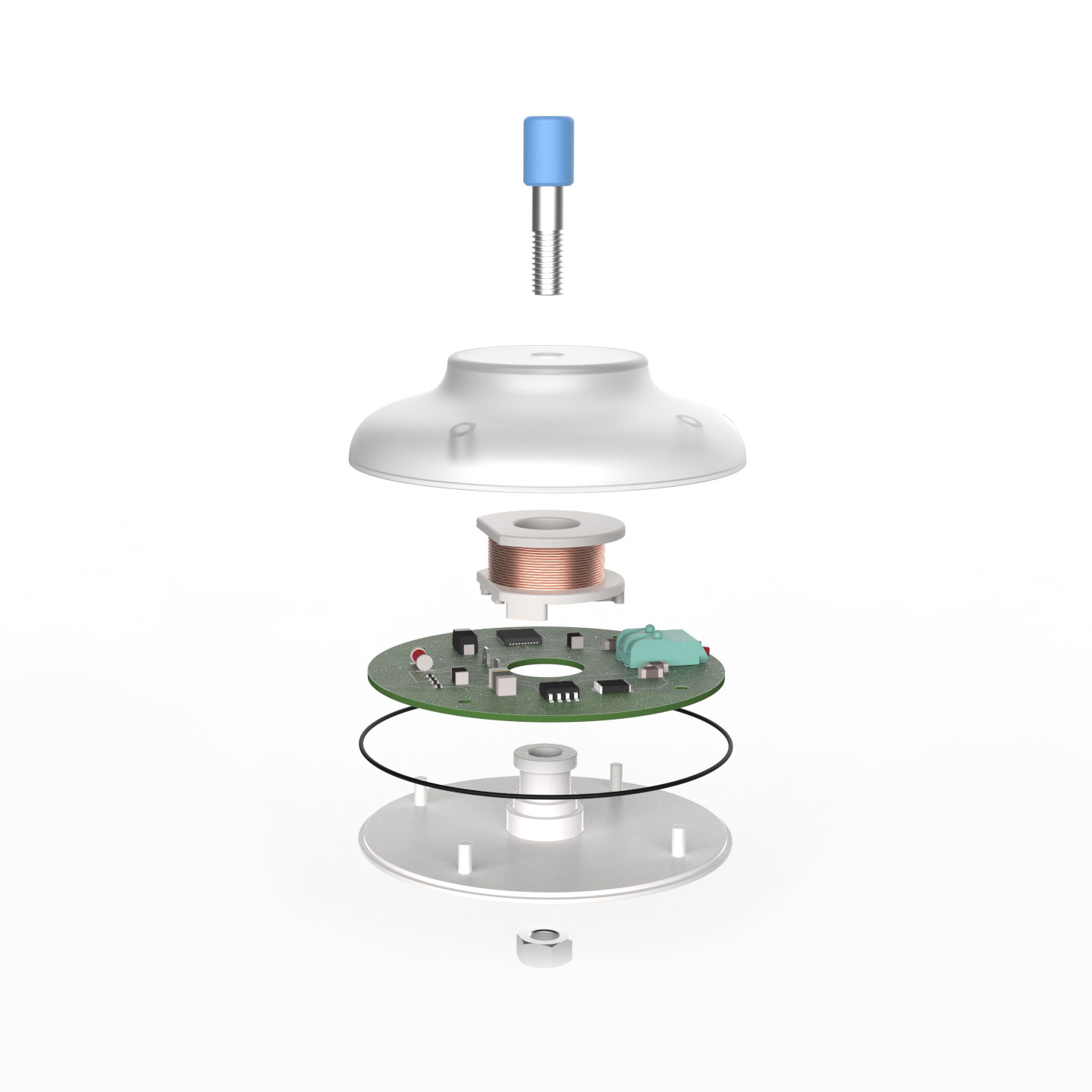

in the second part of the work, three exemplary products are used to visualize what specific solutions can look like and how the principles can be implemented in the product.

︎︎︎ electric toothbrush

translucent housing parts make the components visible and spark curiosity to look inside.

outer interaction points are highlighted in color.

the station is fixed by a nut on the bottom, with a screw that can be unscrewed by hand.

toolless access is made possible by visible plastic snap connectors. their shape explains the locking mechanism and they can be opened reversibly.

toothbrush

station

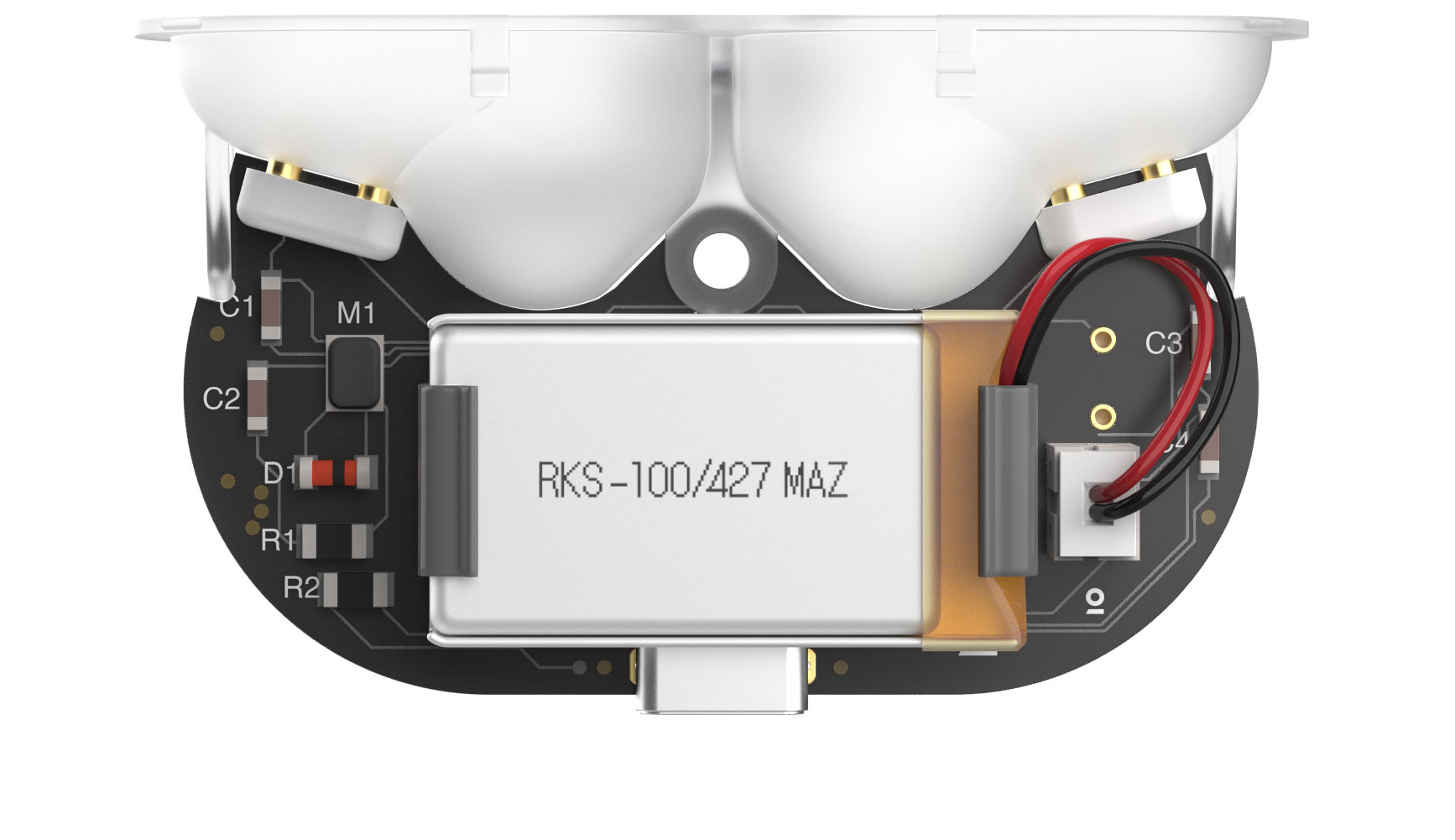

︎︎︎ wireless earbuds

the buds have visible indicators where they can be opened. they can be opened with common household objects, such as a coin. we also use the left-right color coding from the audio field.

the buds have two circuit boards, one that handles charging and power management, and the other that handles connectivity and processes the audio signal.

the connection to the battery is made via contact pins on the boards.

the motherboard in the case is attached to the inner shell via snaps. the entire unit is unlocked by loosening the screw and can be pulled out.

the batteries are connected to the board on both sides by connectors.

buds

case

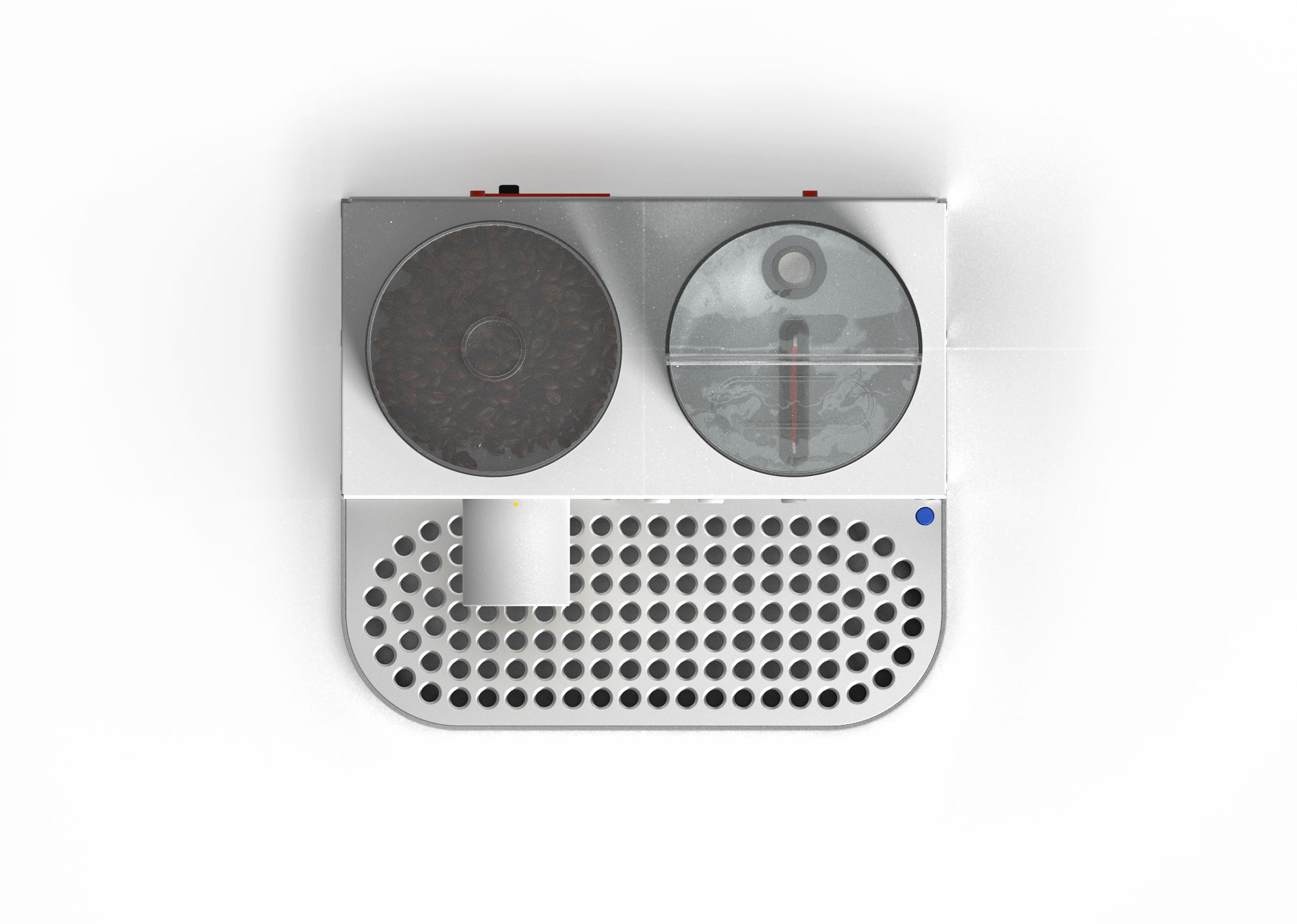

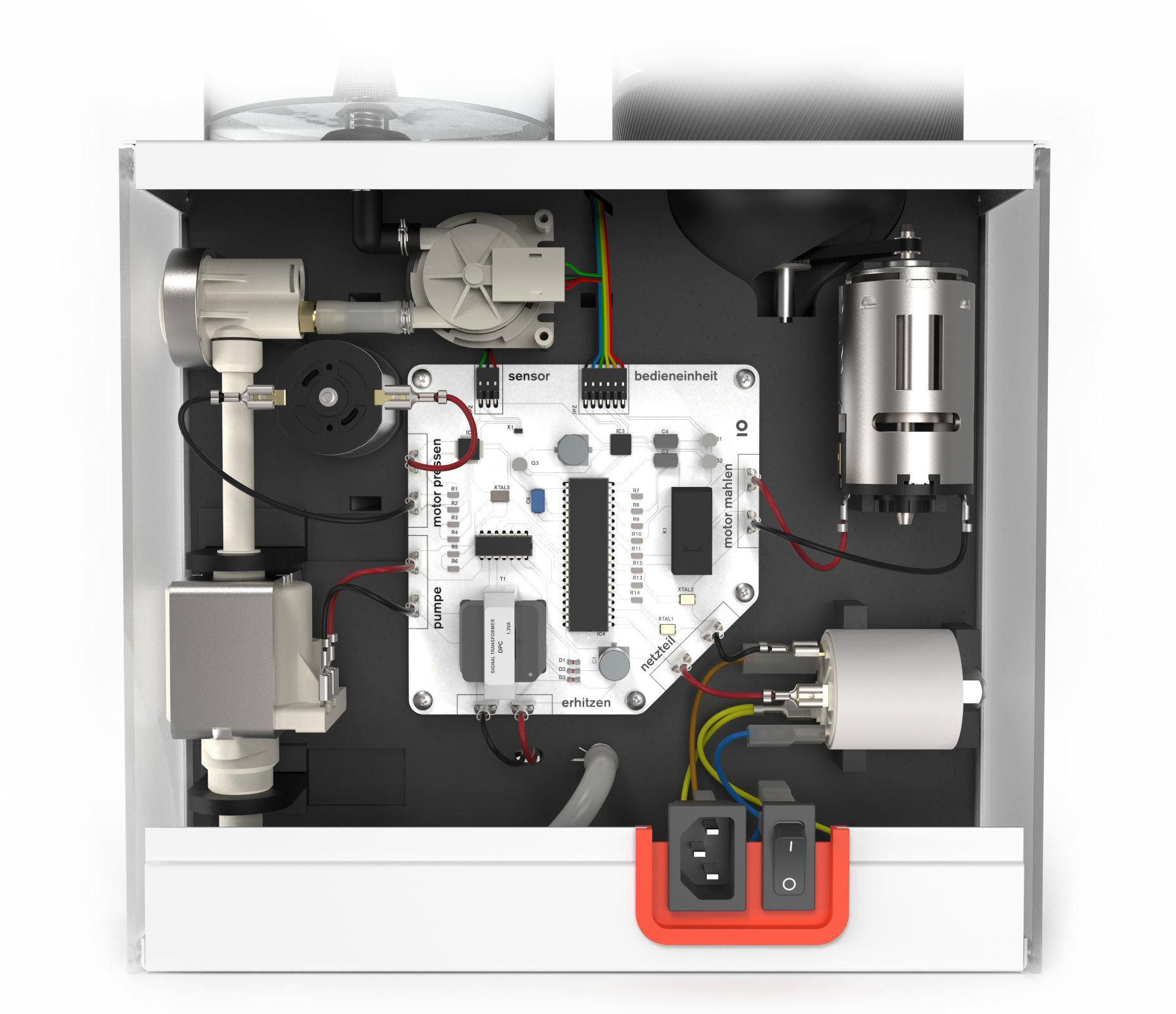

︎︎︎ coffee machine

the coffee machine has been designed so that its workflows are clearly visible and understandable. a major focus is on regular maintenance and the accessibility of components. this is to emphasize maintenance and make repair much easier.

control

panel

panel

when it is necessary to change beans, water or coffee grounds, this is indicated by a blue LED on the control unit. next to the LED, the waste water collection tray indicates via a blue float that the waste water must be emptied.

all elements for maintenance are placed present and marked in yellow. when maintenance is required and as a reminder, a yellow LED lights up on the control unit. the brewing unit can be removed after unlocking it using the two yellow levers on the front and can then be cleaned and serviced.

in the event of a problem, this will be indicated by the malfunction LED lighting up red. the user can then use the hexagonal wrench to loosen the screws on the rear panel, which are also coded in red. once the back panel is removed, the inner workings of the machine are revealed and markings on the housing and circuit board show where which component is located and how they are connected.

coffee machine